Fuel Cell Substrates: A Comprehensive Overview

Fuel Cell Substrates: A Comprehensive Overview

Related Articles: Fuel Cell Substrates: A Comprehensive Overview

- 2025 Mini Cooper Colors: A Vibrant Palette For The Iconic City Car

- 2025 Volvo EX90: The Pinnacle Of Electric Luxury

- Ford Edge Redesigned For 2024: A Comprehensive Overview

- 2025 Fashion Trends: Shaping The Future Of Style

- Volkswagen Bus 2025 Camper: A Modern Twist On A Classic

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Fuel Cell Substrates: A Comprehensive Overview. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Fuel Cell Substrates: A Comprehensive Overview

- 2 Introduction

- 3 Video about Fuel Cell Substrates: A Comprehensive Overview

- 4 Fuel Cell Substrates: A Comprehensive Overview

- 4.1 Types of Fuel Cell Substrates

- 4.2 Properties of Fuel Cell Substrates

- 4.3 Optimization of Fuel Cell Substrates

- 4.4 Applications of Fuel Cell Substrates

- 4.5 Challenges and Future Prospects

- 5 Closure

Video about Fuel Cell Substrates: A Comprehensive Overview

Fuel Cell Substrates: A Comprehensive Overview

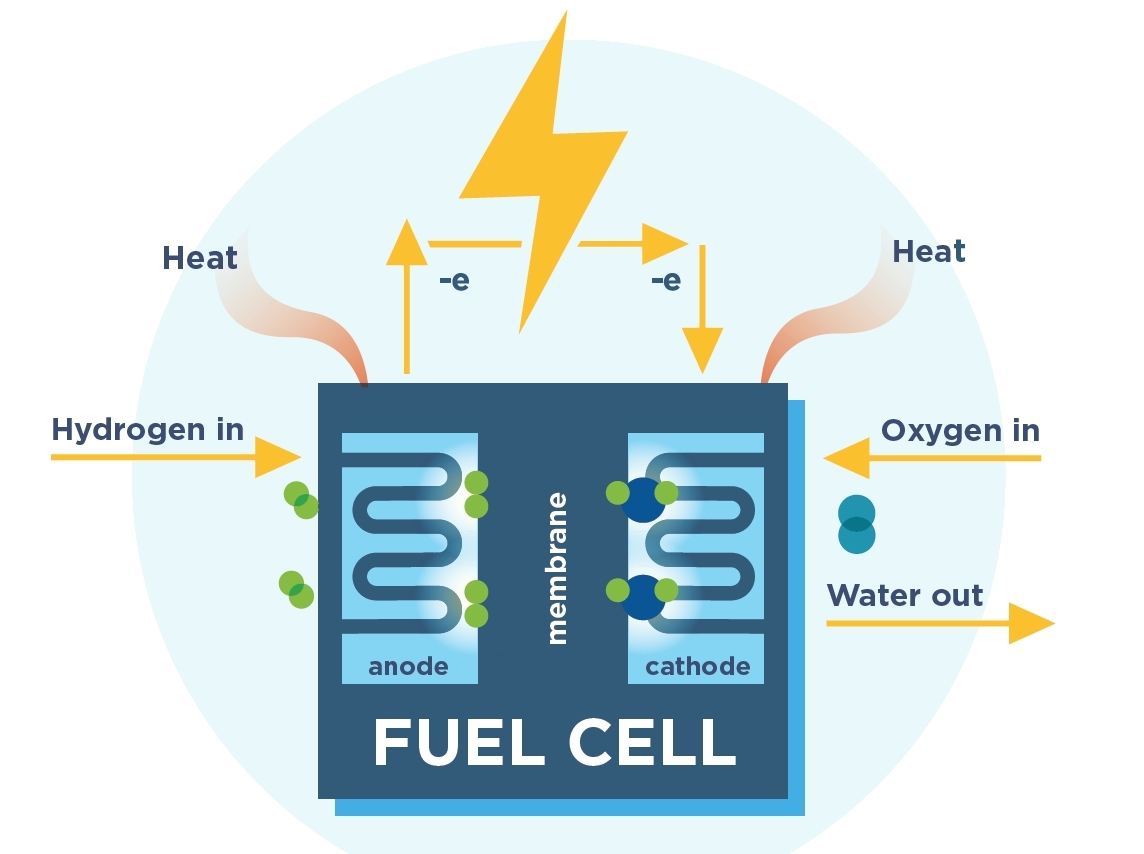

Fuel cells, electrochemical devices that convert chemical energy into electrical energy, have emerged as promising candidates for clean and efficient power generation in various applications. At the heart of fuel cells lies a substrate, a porous material that serves as a support for the electrocatalyst and facilitates the flow of reactants and products. The selection of an appropriate substrate is crucial for optimizing fuel cell performance and durability.

Types of Fuel Cell Substrates

Fuel cell substrates can be broadly classified into two categories based on their materials: metallic and non-metallic.

Metallic Substrates:

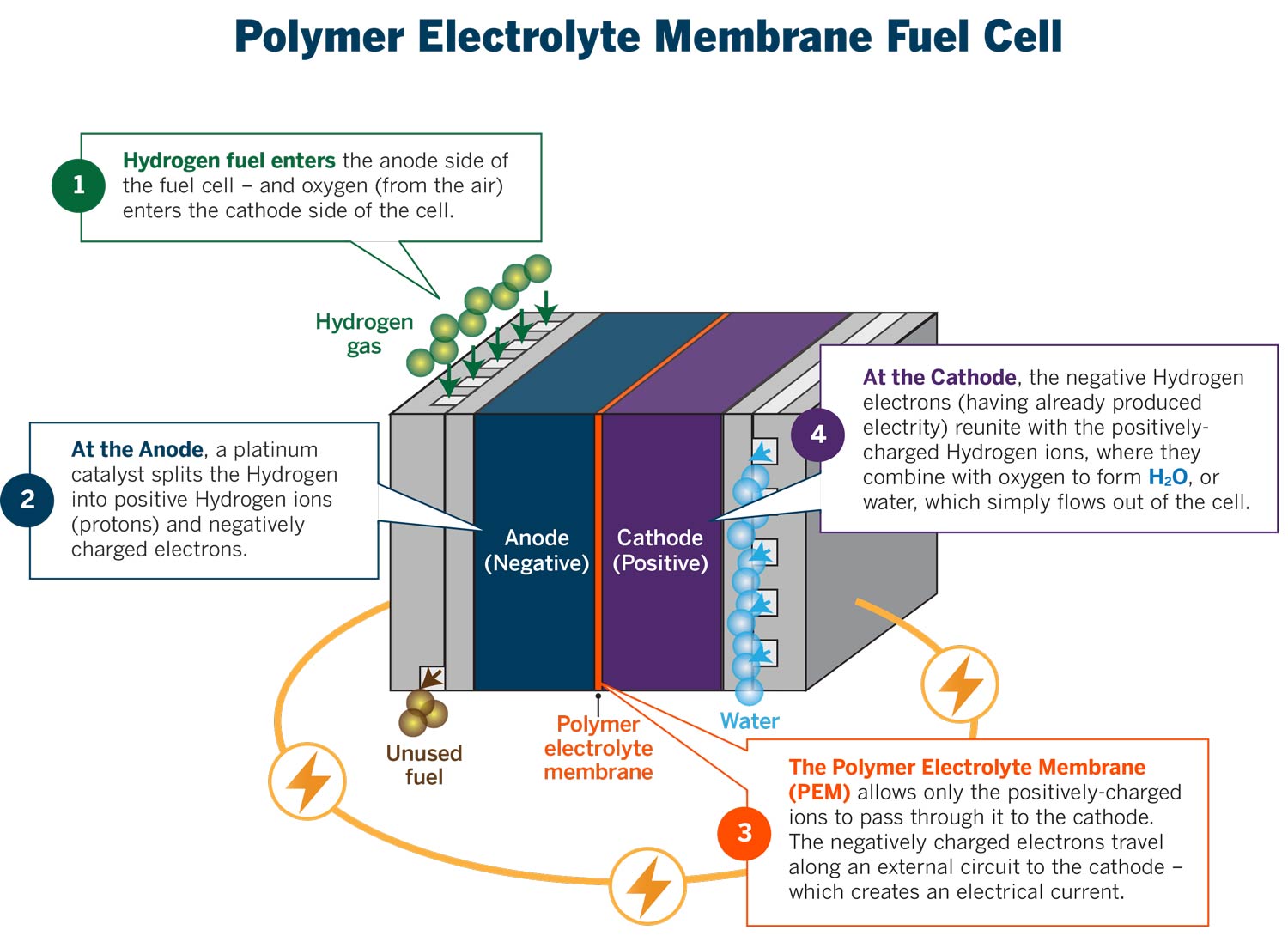

- Stainless steel: Cost-effective, corrosion-resistant, and mechanically robust. Commonly used in proton exchange membrane fuel cells (PEMFCs).

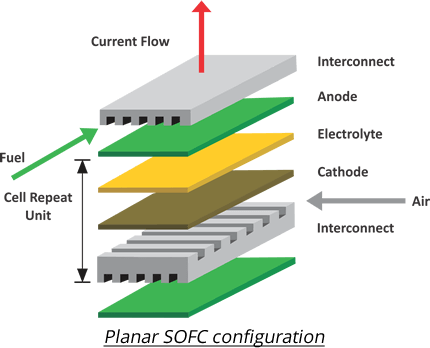

- Titanium: Lightweight, corrosion-resistant, and biocompatible. Used in solid oxide fuel cells (SOFCs) and alkaline fuel cells (AFCs).

- Nickel-based alloys: High electrical conductivity, corrosion resistance, and strength. Suitable for high-temperature fuel cells, such as SOFCs and molten carbonate fuel cells (MCFCs).

Non-Metallic Substrates:

- Carbon-based materials: Graphite, carbon fiber, and carbon cloth. Excellent electrical conductivity, high surface area, and corrosion resistance. Used in PEMFCs and direct methanol fuel cells (DMFCs).

- Ceramic materials: Zirconia, alumina, and yttria-stabilized zirconia (YSZ). Chemically inert, thermally stable, and mechanically strong. Employed in SOFCs and MCFCs.

- Polymer-based materials: Polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), and polybenzimidazole (PBI). Flexible, lightweight, and chemically resistant. Utilized in PEMFCs and DMFCs.

Properties of Fuel Cell Substrates

The selection of a fuel cell substrate depends on its specific properties, which include:

- Porosity: Allows for the flow of reactants and products while providing sufficient support for the electrocatalyst.

- Electrical conductivity: Facilitates electron transfer between the electrocatalyst and the external circuit.

- Corrosion resistance: Prevents degradation due to harsh chemical environments.

- Mechanical strength: Withstands pressure and stress during fuel cell operation.

- Thermal stability: Maintains structural integrity under high temperatures.

- Cost-effectiveness: Enables the production of fuel cells at a competitive price.

Optimization of Fuel Cell Substrates

To maximize fuel cell performance, it is essential to optimize the substrate’s properties. This involves:

- Tuning porosity: Balancing gas permeability and electrocatalyst support.

- Enhancing electrical conductivity: Using conductive materials or applying conductive coatings.

- Improving corrosion resistance: Selecting materials with high chemical inertness or applying protective layers.

- Strengthening mechanical properties: Reinforcing the substrate with fibers or composite materials.

- Reducing cost: Exploring alternative materials and manufacturing techniques.

Applications of Fuel Cell Substrates

Fuel cell substrates find applications in a wide range of fuel cell technologies, including:

- PEMFCs: Powering vehicles, portable devices, and stationary backup systems.

- SOFCs: Generating electricity in stationary applications, such as power plants and industrial facilities.

- MCFCs: Providing high-efficiency power generation for large-scale applications.

- AFCs: Used in aerospace and military applications due to their low noise and high efficiency.

- DMFCs: Compact and portable power sources for consumer electronics and small devices.

Challenges and Future Prospects

Despite significant advancements, challenges remain in the development of fuel cell substrates, including:

- Cost reduction: Exploring low-cost materials and innovative manufacturing processes.

- Durability improvement: Enhancing the substrate’s resistance to degradation and extending its lifespan.

- Optimization for specific applications: Tailoring the substrate’s properties to meet the unique requirements of different fuel cell technologies.

Future research efforts will focus on addressing these challenges and advancing the development of highly efficient, durable, and cost-effective fuel cell substrates. By overcoming these hurdles, fuel cells can unlock their full potential as clean and sustainable energy sources for a wide range of applications.

Closure

Thus, we hope this article has provided valuable insights into Fuel Cell Substrates: A Comprehensive Overview. We hope you find this article informative and beneficial. See you in our next article!